Burckhardt Compression wins major order for LNG Terminal in Germany, supporting energy security and transition

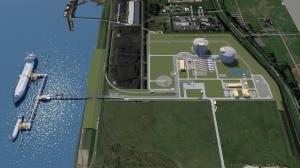

WINTERTHUR, SWITZERLAND, November 29, 2024 /EINPresswire.com/ -- Burckhardt Compression, a leader in reciprocating compressors, has been selected to supply critical Boil-off Gas (BOG) and Pipeline injection compressors (MSO) for a new LNG regasification terminal in Brunsbüttel, Germany. This terminal will play a vital role in securing a stable supply of liquefied natural gas (LNG) for Germany, with regular operations expected to start in 2027.

The new Brunsbüttel terminal aligns with Germany's national strategy to enhance energy security and reduce reliance on coal and nuclear power. Burckhardt Compression's BOG and pipeline injection compressors will ensure safe and efficient LNG handling and injection into Germany’s national gas network.

"For this project, we chose Burckhardt Compression because of their extensive experience with LNG BOG management compressors, the high operational flexibility of their machines, and their proven track record with LNG terminal installations in Europe." states German LNG Terminal.

This contract underlines Burckhardt Compression’s commitment to global energy security and highlights the Company's role in advancing sustainable energy solutions for the future. The LNG sector is projected to grow significantly in the coming years, with traded volumes expected to increase by more than 50% by 2040.

Supporting reliable LNG supply chains efficiency

The LNG supply chain encompasses several critical steps, incl. gas purification, liquefaction, transportation, regasification, and distribution. As global demand for LNG continues to rise, terminals are transforming into multifaceted hubs.

Burckhardt Compression’s specially designed compressors, including gas tight Laby® compressor, offer robust solutions with maximum operational flexibility for handling BOG operations. Over the years, the Laby® compressor has set the benchmark for reliability and low lifecycle costs. It remains the most preferred compressor type on the market for oil-free compression duties, particularly for cryogenic liquid gas storage applications.

Tina Witteczek

Burckhardt Compression AG

+41 52 261 55 38

email us here

Visit us on social media:

LinkedIn

Distribution channels: Business & Economy, Energy Industry, Environment

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.

Submit your press release