Fusing Machine Market Reaching USD 886.20 Million by 2034, Driven by Increased Demand in Textile Industry

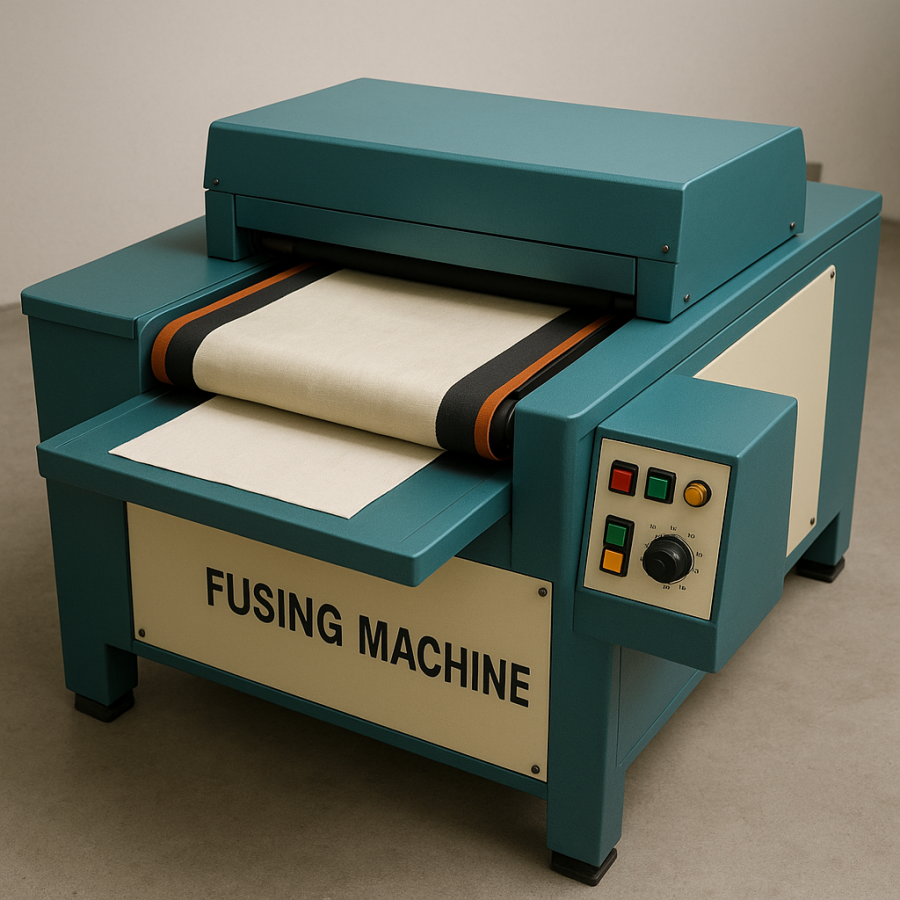

Fusing machines advance textile manufacturing with automation and continuous press systems, improving precision, efficiency, and reducing production costs.

NEWARK, DE, UNITED STATES, May 12, 2025 /EINPresswire.com/ -- The global fusing machine market is poised for significant growth in the coming decade. According to a recent study, the market is expected to grow from USD 533.80 million in 2024 to USD 886.20 million by 2034, with a compound annual growth rate (CAGR) of 5.20%. This growth can be attributed to the increasing demand for fusing machines in the textile and garment manufacturing industries, where they are used for bonding fabrics through heat and pressure. Fusing machines are essential in the production of durable, high-quality garments, making them indispensable to the modern apparel industry.

Fusing machines play a vital role in the textile manufacturing process, especially in the garment industry, where precision and speed are crucial. As the demand for high-quality garments continues to rise, fusing machines are becoming more advanced, with innovations that enhance efficiency and reduce production costs. Continuous press machines, which dominate the market, are particularly in demand due to their ability to deliver consistent results and integrate seamlessly into existing manufacturing lines, which significantly boosts production rates and minimizes installation challenges.

The market is also witnessing a shift toward automation, with fully automatic fusing machines gaining traction. These machines offer unparalleled precision and ease of operation, ensuring consistent performance and minimizing human error. As the textile industry becomes more competitive, the demand for such automated solutions is expected to continue rising. Fully automatic machines are also ideal for mass production, where high volumes of garments need to be produced quickly and efficiently.

Another key trend in the fusing machine market is the growing adoption of continuous press technology. Continuous press fusing machines offer improved productivity by enabling higher throughput and reducing the time required to process fabrics. The efficiency of these machines makes them particularly appealing to manufacturers looking to meet the growing demand for garments while maintaining high-quality standards.

𝗚𝗮𝗶𝗻 𝗩𝗮𝗹𝘂𝗮𝗯𝗹𝗲 𝗜𝗻𝘀𝗶𝗴𝗵𝘁𝘀 𝗳𝗿𝗼𝗺 𝗜𝗻𝗱𝘂𝘀𝘁𝗿𝘆 𝗘𝘅𝗽𝗲𝗿𝘁𝘀 𝘁𝗼 𝗦𝗵𝗮𝗽𝗲 𝗬𝗼𝘂𝗿 𝗚𝗿𝗼𝘄𝘁𝗵 𝗦𝘁𝗿𝗮𝘁𝗲𝗴𝗶𝗲𝘀. 𝗔𝗰𝗰𝗲𝘀𝘀 𝗼𝘂𝗿 𝗦𝗮𝗺𝗽𝗹𝗲 𝗥𝗲𝗽𝗼𝗿𝘁 𝗡𝗼𝘄: https://www.futuremarketinsights.com/reports/sample/REP-GB-19176

𝗥𝗲𝗽𝗼𝗿𝘁 𝗖𝗼𝘃𝗲𝗿𝗮𝗴𝗲 & 𝗗𝗲𝗹𝗶𝘃𝗲𝗿𝗮𝗯𝗹𝗲𝘀

This report provides a comprehensive analysis of the fusing machine market, detailing market segmentation, key market trends, regional insights, and competitive landscape. The report covers various segments such as machine types (continuous press and others), automation levels (fully automatic and manual), and end-user industries. Key players, market forecasts, and growth drivers are also explored in detail.

𝗞𝗲𝘆 𝗙𝗮𝗰𝘁𝗼𝗿𝘀 𝗦𝗵𝗮𝗽𝗶𝗻𝗴 𝗠𝗮𝗿𝗸𝗲𝘁 𝗗𝘆𝗻𝗮𝗺𝗶𝗰𝘀

Several factors are driving the fusing machine market, including increased demand for high-quality, durable textiles and garments, the push for automation in manufacturing, and advancements in continuous press technology. Moreover, the integration of fusing machines with existing production lines is an added advantage, enabling manufacturers to meet rising production demands with minimal disruption.

𝗠𝗮𝗿𝗸𝗲𝘁 𝗗𝘆𝗻𝗮𝗺𝗶𝗰𝘀 𝗼𝗳 𝗙𝘂𝘀𝗶𝗻𝗴 𝗠𝗮𝗰𝗵𝗶𝗻𝗲 𝗶𝗻 𝗖𝗵𝗶𝗻𝗮 𝗔𝗶𝗱𝗲𝗱 𝗯𝘆 𝗗𝗼𝗺𝗶𝗻𝗮𝗻𝘁 𝗧𝗲𝘅𝘁𝗶𝗹𝗲 𝗜𝗻𝗱𝘂𝘀𝘁𝗿𝘆

China, as the world’s largest textile producer, continues to be a dominant player in the fusing machine market. The robust textile industry in China requires state-of-the-art fusing machines to ensure high-quality production while maintaining cost efficiency. As China’s textile sector embraces more advanced machinery, the demand for continuous press fusing machines is expected to grow substantially.

The growth of the fusing machine market in China is also supported by the increasing shift towards automation in textile manufacturing. With China’s focus on modernizing its textile industry and optimizing production processes, fusing machines are seeing widespread adoption, making them an integral part of the nation’s industrial growth.

𝗔𝗽𝗽𝗲𝗮𝗹 𝗦𝗲𝗰𝘁𝗼𝗿 𝗕𝗲𝗻𝗲𝗳𝗶𝘁𝘀 𝗙𝘂𝘀𝗶𝗻𝗴 𝗔𝗽𝗽𝗹𝗶𝗮𝗻𝗰𝗲 𝗜𝗻𝗱𝘂𝘀𝘁𝗿𝘆 𝗚𝗹𝗼𝗯𝗮𝗹 𝗠𝗮𝗿𝗸𝗲𝘁

The appeal of fusing machines extends beyond textile production to the global garment industry, where the need for high-quality and precise fabric bonding is paramount. Fusing machines ensure a perfect and durable bond between fabric layers, making them a critical component in garment manufacturing, particularly for products requiring precise shaping and durability.

The growing consumer demand for premium, ready-to-wear garments is also boosting the global fusing machine market. These machines contribute to the ability of garment manufacturers to meet the demand for stylish, durable, and high-quality apparel, further driving the global market.

𝗜𝗻𝗻𝗼𝘃𝗮𝘁𝗶𝗼𝗻 𝗪𝗮𝘃𝗲 𝗼𝗳 𝗙𝘂𝘀𝗶𝗻𝗴 𝗗𝗲𝘃𝗶𝗰𝗲 𝗠𝗮𝗿𝗸𝗲𝘁 𝗶𝗻 𝗚𝗹𝗼𝗯𝗮𝗹 𝗠𝗮𝗿𝗸𝗲𝘁

Technological advancements in fusing machines are revolutionizing the textile industry. Innovations like improved heating systems, more energy-efficient machines, and advanced pressure control systems are enhancing the performance of fusing machines. These innovations not only improve the quality of the final product but also contribute to operational cost savings and greater production flexibility.

Moreover, the integration of artificial intelligence (AI) and the Internet of Things (IoT) in fusing machines is expected to transform the market. These technologies offer enhanced machine monitoring, predictive maintenance, and real-time performance analysis, ensuring higher efficiency and minimal downtime.

𝗞𝗲𝘆 𝗧𝗮𝗸𝗲𝗮𝘄𝗮𝘆𝘀

The fusing machine market is on a strong growth trajectory, propelled by continuous press technology, automation, and innovations that optimize production. With the market expected to grow from USD 533.80 million in 2024 to USD 886.20 million by 2034, manufacturers are investing in more efficient and automated fusing machines to meet the rising demand for high-quality textiles. The widespread adoption of continuous press technology and automated systems will continue to reshape the market, providing businesses with tools to boost productivity and reduce operational costs.

𝗕𝗿𝗼𝘄𝘀𝗲 𝗙𝘂𝗹𝗹 𝗥𝗲𝗽𝗼𝗿𝘁 𝗛𝗲𝗿𝗲: https://www.futuremarketinsights.com/reports/fusing-machine-market

𝗙𝘂𝘀𝗶𝗻𝗴 𝗺𝗮𝗰𝗵𝗶𝗻𝗲𝘀 𝗱𝗲𝗹𝗶𝘃𝗲𝗿 𝗰𝗼𝗻𝘀𝗶𝘀𝘁𝗲𝗻𝘁 𝗵𝗲𝗮𝘁 𝗮𝗻𝗱 𝗽𝗿𝗲𝘀𝘀𝘂𝗿𝗲 𝗳𝗼𝗿 𝗳𝗹𝗮𝘄𝗹𝗲𝘀𝘀 𝗳𝗮𝗯𝗿𝗶𝗰 𝗯𝗼𝗻𝗱𝗶𝗻𝗴

Fusing machines offer unmatched consistency in heat and pressure application, ensuring flawless fabric bonding without compromising the integrity of the material. This precision is especially vital in the garment manufacturing process, where fabric strength and aesthetic quality are critical.

The reliability of fusing machines in delivering consistent results makes them an essential tool for manufacturers aiming to meet stringent quality standards. This feature enables textile companies to produce garments with uniform appearance and durability, which is vital for maintaining customer satisfaction and competitiveness in the market.

𝗘𝗻𝘀𝘂𝗿𝗲 𝗽𝗿𝗲𝗰𝗶𝘀𝗲 𝗮𝗻𝗱 𝗱𝘂𝗿𝗮𝗯𝗹𝗲 𝗮𝗱𝗵𝗲𝘀𝗶𝗼𝗻 𝗶𝗻 𝗴𝗮𝗿𝗺𝗲𝗻𝘁 𝗺𝗮𝗻𝘂𝗳𝗮𝗰𝘁𝘂𝗿𝗶𝗻𝗴 𝘄𝗶𝘁𝗵 𝗮𝗱𝘃𝗮𝗻𝗰𝗲𝗱 𝗳𝘂𝘀𝗶𝗻𝗴 𝗺𝗮𝗰𝗵𝗶𝗻𝗲𝘀

Advanced fusing machines provide the precision required for perfect adhesion in garment production. These machines ensure that the fabric is bonded at optimal pressure and temperature, leading to strong, durable seams that can withstand wear and tear.

With the ability to fuse fabric layers with minimal distortion, these machines guarantee consistent, high-quality results, making them essential for mass production in the apparel industry.

𝗔𝗰𝗵𝗶𝗲𝘃𝗲 𝘂𝗻𝗶𝗳𝗼𝗿𝗺 𝗳𝘂𝘀𝗶𝗻𝗴 𝗿𝗲𝘀𝘂𝗹𝘁𝘀 𝘄𝗶𝘁𝗵 𝗺𝗶𝗻𝗶𝗺𝗮𝗹 𝗳𝗮𝗯𝗿𝗶𝗰 𝗱𝗶𝘀𝘁𝗼𝗿𝘁𝗶𝗼𝗻 𝘂𝘀𝗶𝗻𝗴 𝗮𝘂𝘁𝗼𝗺𝗮𝘁𝗲𝗱 𝗳𝘂𝘀𝗶𝗻𝗴 𝘀𝘆𝘀𝘁𝗲𝗺𝘀

Automated fusing systems are designed to achieve uniform bonding across large volumes of fabric, minimizing distortion and ensuring consistent quality. These systems enhance efficiency in high-speed production environments and reduce the need for manual intervention.

By offering precise control over the fusing process, automated systems allow manufacturers to meet the growing demand for large-scale garment production while maintaining high-quality standards.

𝗜𝗻𝗱𝘂𝘀𝘁𝗿𝗶𝗮𝗹 𝗖𝗿𝘆𝘀𝘁𝗮𝗹𝗹𝗶𝘇𝗲𝗿 𝗠𝗮𝗿𝗸𝗲𝘁 𝗞𝗲𝘆 𝗣𝗹𝗮𝘆𝗲𝗿𝘀

The leading players in the fusing machine market include:

- Veit-Group

- HASHIMA

- McElroy

- Shanghai Weishi Mechanical

- GF Central Plastics

- Auto Garment

- Strima

- Sharp International

These companies are instrumental in driving innovation and providing state-of-the-art fusing machines for the textile industry, continually advancing their products to meet the needs of a growing global market.

𝗘𝗻𝗴𝗶𝗻𝗲𝗲𝗿𝗲𝗱 𝗳𝗼𝗿 𝗲𝗳𝗳𝗶𝗰𝗶𝗲𝗻𝗰𝘆, 𝗳𝘂𝘀𝗶𝗻𝗴 𝗺𝗮𝗰𝗵𝗶𝗻𝗲𝘀 𝗼𝗽𝘁𝗶𝗺𝗶𝘇𝗲 𝘁𝗵𝗿𝗼𝘂𝗴𝗵𝗽𝘂𝘁 𝗶𝗻 𝘁𝗲𝘅𝘁𝗶𝗹𝗲 𝗽𝗿𝗼𝗱𝘂𝗰𝘁𝗶𝗼𝗻

Fusing machines are engineered for high efficiency, ensuring that textile manufacturers can meet the ever-growing demand for fast and cost-effective production. These machines optimize throughput by reducing production time while maintaining high quality.

With the integration of cutting-edge technology, fusing machines offer enhanced productivity and minimal downtime, making them a valuable investment for businesses aiming to scale operations and improve their bottom line.

𝗥𝗲𝗴𝗶𝗼𝗻𝗮𝗹 𝗔𝗻𝗮𝗹𝘆𝘀𝗶𝘀

- North America: A key market for fusing machines, driven by the increasing demand for advanced textile production technologies.

- Latin America: Growing textile production in countries like Brazil and Mexico fuels the demand for fusing machines.

- Western Europe: Home to many established textile manufacturers, the region continues to be a major player in the fusing machine market.

- Eastern Europe: Increased automation in the textile industry is boosting demand for fusing machines in Eastern Europe.

- East Asia: China remains the dominant market in East Asia, with the largest demand for fusing machines in textile production.

- South Asia & Pacific: Rising textile production in India and other South Asian countries drives market growth.

- Middle East & Africa: Demand for high-quality textile products is increasing, driving the adoption of fusing machines.

𝗟𝗮𝘁𝗲𝘀𝘁 𝗠𝗮𝗻𝘂𝗳𝗮𝗰𝘁𝘂𝗿𝗶𝗻𝗴 𝗘𝗾𝘂𝗶𝗽𝗺𝗲𝗻𝘁 𝗥𝗲𝗽𝗼𝗿𝘁𝘀: https://www.futuremarketinsights.com/industry-analysis/manufacturing-equipment

𝗞𝗲𝘆 𝗦𝗲𝗴𝗺𝗲𝗻𝘁𝘀

By Type:

- Flatbed

- Continuous Press

- Rotary

By Automation Level:

- Manual

- Semi-automatic

- Fully Automatic

By Application:

- Garment Manufacturing

- Automotive Upholstery

- Home Textiles

- Other

By Region:

- North America

- Latin America

- Western Europe

- Eastern Europe

- East Asia

- South Asia and Pacific

- Middle East and Africa

𝗘𝘅𝗽𝗹𝗼𝗿𝗲 𝗙𝗠𝗜’𝘀 𝗘𝘅𝘁𝗲𝗻𝘀𝗶𝘃𝗲 𝗖𝗼𝘃𝗲𝗿𝗮𝗴𝗲 𝗼𝗻 𝗜𝗻𝗱𝘂𝘀𝘁𝗿𝗶𝗮𝗹 𝗔𝘂𝘁𝗼𝗺𝗮𝘁𝗶𝗼𝗻 𝗗𝗼𝗺𝗮𝗶𝗻:

The smart power technologies market is expected to grow at a CAGR of 9.7% from 2025 to 2035, increasing from USD 211.11 Million in 2025 to USD 532.81 Million by 2035.

The foot suction valve market is expected to increase from USD 269.5 million in 2024 to USD 491.8 million in 2034.

𝗔𝗯𝗼𝘂𝘁 𝗙𝘂𝘁𝘂𝗿𝗲 𝗠𝗮𝗿𝗸𝗲𝘁 𝗜𝗻𝘀𝗶𝗴𝗵𝘁𝘀 (𝗙𝗠𝗜)

Future Market Insights (FMI) is a leading provider of market intelligence and consulting services, serving clients in over 150 countries. FMI is headquartered in Dubai and has delivery centers in the United Kingdom, the United States, and India. FMI's latest market research reports and industry analysis helps businesses navigate challenges and make critical decisions with confidence and clarity amidst breakneck competition. Our customized and syndicated market research reports deliver actionable insights that drive sustainable growth. A team of expert-led analysts at FMI continuously tracks emerging trends and events in a broad range of industries to ensure that our clients prepare for the evolving needs of their consumers.

Join us as we commemorate 10 years of delivering trusted market insights. Reflecting on a decade of achievements, we continue to lead with integrity, innovation, and expertise.

𝗖𝗼𝗻𝘁𝗮𝗰𝘁 𝗨𝘀:

Future Market Insights Inc.

Christiana Corporate, 200 Continental Drive,

Suite 401, Newark, Delaware - 19713, USA

T: +1-347-918-3531

For Sales Enquiries: sales@futuremarketinsights.com

Website: https://www.futuremarketinsights.com

LinkedIn| Twitter| Blogs | YouTube

Ankush Nikam

Future Market Insights, Inc.

+ +91 90966 84197

email us here

Visit us on social media:

LinkedIn

Facebook

YouTube

X

Other

Distribution channels: Business & Economy

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.

Submit your press release